BRASS JIC 37 DEGREE FLARE FITTINGS - FASTFITTINGS.COM

JIC fittings are machined to have a base of 37 degrees. Used in fuels and other fluids applications, the design is made to tolerate low to medium mechanical strains. Shop JIC 37 degree flare fittings at FastFittings.com. View full article →Brass Hose Barb Fittings - FastFittings.com

There are different types of port connections that can be made with the brass hose barb fitting according to the nature of the port. While some ports require straight thread connections, others can only be fitted with a beaded hose barb. To make sure you have the correct connection size, please contact us for assistance Sales@FastFittings.com or 866-515-5481. View full article →NPT Thread - American Standard Pipe Taper Thread - FastFittings.com

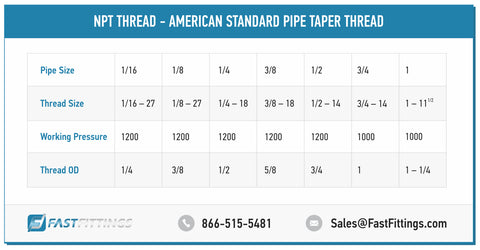

NPT (Nаtiоnаl Pipe Thread) ѕеаlѕ аrе thе mоѕt popular type оf ѕеаl fоr pressure саlibrаtiоn systems in the United States. Shop Brass JIC 37 Degree Flare Fittings at FastFittings.com. View full article →How are forged and extruded Brass Fittings made?

Brass Fittings

A brass fitting is manufactured from rods made out of brass. They do not require any type of tubing preparation such as soldering or flaring. Available in a wide range of styles and sizes, the ideal operating temperatures in which these fittings can be used are 73 degrees Fahrenheit if copper tubing is used. Although brass fittings can be used in a variety of pressure settings, gas pipes are not recommended.

Extruded brass

With the extrusion method it is possible to draw brass rods into customized shapes according to the desired tolerance of the fitting. This is an effective way of avoiding pin holes, sand holes and splits. It is after the extrusion process that the brass fittings can now be machined to make a perfect piece. This one piece finished part is solid in nature and does not contain seams or brazed joints. Brass pipe fittings that are required to be strong, non-porous and dense in the longitudinal direction require this type of manufacturing method.

Forged brass

As with the extruded brass fittings, the kinds of fittings made from forged brass are made using the same method but contain a different temper and combination of chemicals. The process begins with cutting the brass bars to the length of the fitting being made. It is then heated to achieve permeability and then pressed in between dies at high pressure. Cooling then follows after which the flash is trimmed and machining of the forging blank done to finish the fitting.

Regulatory laws

In January 2014, the United States passed laws prohibiting the use of brass fittings in pipes and piping systems that convey water that is intended for human consumption with a focus on drinking and cooking water. This is a move that deliberately aims to eliminate the incidents of lead poisoning in these kinds of pipes. To ensure compliance to this law, most companies are now manufacturing compliant products. Compliant fittings in the market today include brass fittings, braided water connectors, brass stops and hot water heater connectors. It is easy for consumers to know which products have complied with this law and which ones they should keep away from just by locating the checkmark on the package.

If you require help on how to determine compliance of brass fittings with lead regulations or in selecting a suitable NPT thread fitting to use for your specific need, please contact sales@fastfittings.com or call 866-515-5481.

PIPE THREAD SIZES - MAKING SENSE OF PIPE THREADS

PIPE THREAD SIZES - MAKING SENSE OF PIPE THREADS

The most common global pipe thread forms are:

- NPT American Standard Pipe Taper Thread

- NPSC American Standard Straight Coupling Pipe Thread

- NPTR American Standard Taper Railing Pipe Thread

- NPSM American Standard Straight Mechanical Pipe Thread

- NPSL American Standard Straight Locknut Pipe Thread

- NPTF American Standard Pipe Thread Tapered (Dryseal)

- BSPP British Standard Pipe Thread Parallel

- BSPT British Standard Pipe Thread Tapered Plastic injection molded thread forms are manufactured to ANSI B2.1 and SAE J476 standards.

Pipe Thread Sizes Pipe thread sizes are based on an inside diameter (ID) or flow size. For example, “1/2–14 NPT” identifies a pipe thread with a nominal inside diameter of 1/2 inch and 14 threads to the inch, made according to the NPT standard. If “LH” is added, the pipe has a left hand thread.

The word “tapered” in several of the above names points to the big difference between many pipe threads and those on bolts and screws. Many pipe threads must make not only a mechanical joint but also a leakproof hydraulic seal. This is accomplished by the tapered thread form of the male matching the thread form of the female tapered thread and the use of pipe sealant to fill any voids between the two threads which could cause a spiral leak. The bottoms of the threads aren't on a cylinder, but a cone; they taper. The taper is 1/16 inch in an inch, which is the same as 3/4 inch in a foot. Because of the taper, a pipe thread can only screw into a fitting a certain distance before it jams.

The standard specifies this distance as the length of hand tight engagement, the distance the pipe thread can be screwed in by hand. It also specifies another distance – the effective thread, this is the length of the thread which makes the seal on a conventional machined pipe thread. For workers, instead of these distances, it is more convenient to know how many turns to make by hand and how many with a wrench. A simple rule of thumb for installing tapered pipe threads, both metal and plastic, is finger tight plus one to two turns with a wrench. Torque installation values can be determined per application, but due to the variations involved in pipe joints such as disimiliar materials of male and female threads, type of sealants used, and internal variations in product wall thickness, a standard torque specification cannot be generically applied.

The following table shows the distances and number of turns called for in the standard. A tolerance of plus or minus one turn is allowed, and in practice threads are often routinely cut shorter than the standard specifies. All dimensions are in inches.

Brass Fittings: https://fastfittings.com/pages/collections/brass-fittings

American Standard Taper Pipe External Thread Nominal size Actual OD Threads per inch Length of engagement (tightened by hand) Length of effective thread 1/8 0.407 27 0.124 ≈ 3.3 turns 0.260 1⁄4 0.546 18 0.172 ≈ 3.1 turns 0.401 3/8 0.681 18 0.184 ≈ 3.3 turns 0.408 1/2 0.850 14 0.248 ≈ 3.4 turns 0.534 3/4 1.060 14 0.267 ≈ 3.7 turns 0.546 1 1.327 11.5 0.313 ≈ 3.6 turns 0.682

Taper/Parallel Threaded Joints Despite the standards created to maintain uniform fittings, tapered pipe threads are inexact and during the course of use and repair the threads can become damaged and susceptible to leakage. The area where the crest and the root of the thread meet can form a spiral leak path no amount of tightening will eliminate. A pressure tight joint is achieved by the compression in the threads resulting from tightening. This compression and sealing occurs in the first few turns of the internal thread. As wrenching takes place, material from both the male and female threads deform into each other. This ensures full thread contact which minimizes spiral leakages.

Variations between injection-molded plastic and machined metal thread forms can occur due to different manufacturing processes. Pipe threads were originally designed as machined thread forms. With the use of thermoplastics and plastic injection molding in the manufacture of plastic pipe thread forms, mold shrinkage and plastic sink make it difficult to insure leak free joints. For this reason, the use of a Teflon based sealant is recommended on all plastic pipe threads. The most common form of sealant is Teflon tape wrapped 2 to 3 turns around the male thread before assembly. Liquid Teflon based sealants are also used successfully to ensure a pressure tight seal. It is always important to use care when applying sealants to avoid introducing the sealant material into the system flow path.

The following sections show examples of how different threads are used and issues that can arise in attempting to create a leak free connection.

- When a BSPT tapered male thread is tightened into a straight female thread (BSPP) the seal can only be made at the base of the female port with 1 or 2 threads. Sealing is compromised by the lack of thread form control in BSP specifications. Variation in crests and roots may cause a mismatch in the thread and create a spiral leak. Thread sealant is required to seal this combination. Using both tapered male and female BSPT threads would offer a better chance of sealing since you are now matching the taper of the male and female thread. This offers more threads a chance of sealing against spiral leakage. Crest and root control is still missing, but with thread sealant, a pressure tight joint would be easier to accomplish. A number of variations of the NPT thread have been introduced to overcome the problem of spiral leakage and are known as Dryseal threads (See SAE standard J476).

- The best known is the NPTF (F for Fuel). With this thread design, there are controls on the crests and roots of both the male and the female threads to ensure the crest crushes or displaces material into the root of the mating thread. The interference fit between the crest of one thread and the root of the other, along with the thread flanks matching, seals against spiral leakage.

- A variation of the Dryseal thread is the NPSF (National Pipe Straight Fuel). It is used for internal threads and a NPTF external thread can be screwed. GLOBAL THREAD Works with Inch or Metric Threads "Global Thread" fittings can be assembled with female threads produced to the following standards: Tapered NPTF Parallel (BSPP, BSP, ISO 7) Tapered (BSPT, PT, ISO7, ISO 228).